Production

Facade Panels

- Precast wall panels, which can be produced with partial insulation, can be manufactured in horizontal, vertical, flat, and ribbed designs.

- This system, which also benefits from post-tensioned element production technology, allows the construction of structures with a span of 30m and a spacing of 10m between axes.

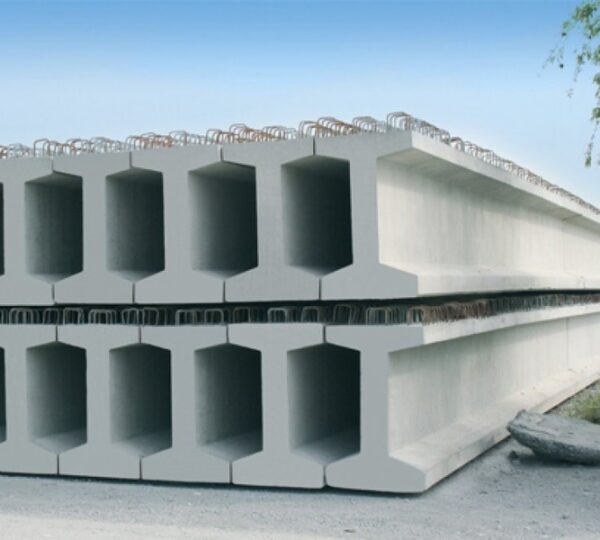

Floor Elements

- As an alternative to traditional floor production, which is the most challenging production item due to scaffolding and casting conditions, the developed precast floor elements allow for spanning large openings and carrying heavy loads in structures.

-

In this element, produced as hollow core flooring or TT flooring, a post-tensioned construction system is used.

İmalati yapilabilinen kalınlıklar : 20cm /25 cm /30 cm

Bridge Beam

- These precast beams, produced using the post-tensioned manufacturing method, can be used in bridge viaducts and overpasses, allowing spans of up to 30m.

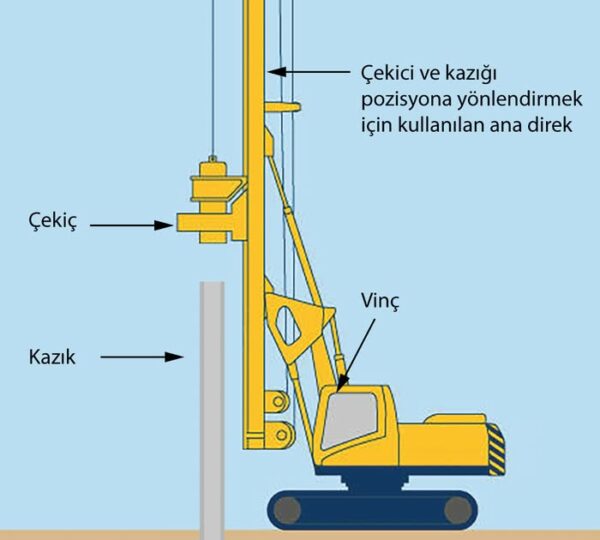

Precast Fake Piles

- Precast driven piles are high-performance structural elements preferred in ground improvement and foundation systems.

- High Carrying Capacity: Precast piles produced in a factory environment have high load-bearing capacity due to homogeneous concrete quality and controlled reinforcement placement.

- Quality Control: Ensuring quality control throughout the production process increases the durability and reliability of the piles. Defects can be detected and addressed during the production stage.

- Various Section Options: Square, circular, octagonal and other cross-section options can offer project-specific solutions.